- Home

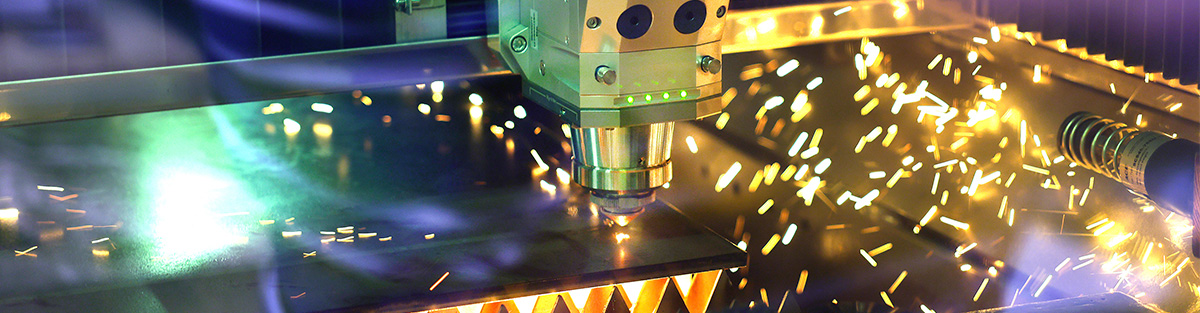

- Laser cutting as a powerful cutting process - Advantages in short

Created on:

Laser cutting as a powerful cutting process - Advantages in short

Laser cutting is a powerful process that meets high quality standards and offers versatile applications in the automotive, electronics, metalworking or medical industries. Some of the main advantages of laser cutting are:

Precision: Laser cutting enables exceptionally high cutting accuracy and precision. By focusing the laser beam on a small area, the material can be cut very precisely. This allows for fine cuts and tight tolerances.

Versatility: Laser cutting is extremely versatile and can cut a wide range of materials, including metals such as steel, stainless steel or aluminum, as well as plastics, wood, glass or stone and more. It can likewise handle different material thicknesses with ease.

Non-contact processing: in laser cutting, the cut is made without contact, as the laser beam cuts the material without touching it. This minimizes damage or contamination to the workpiece. Alternative cutting processes incur high ongoing tooling costs, especially for hard, brittle or high-strength materials. This is not the case with non-contact processing in laser cutting.

Speed: Laser cutting enables high production speeds. The laser beam moves quickly over the material and cuts it in a continuous process. As a result, short processing times and high production rates can be achieved.

Flexibility: Laser cutting offers great flexibility in terms of cutting geometry. Complex shapes, small recesses, filigree patterns and even engravings can be realized with high precision. This opens up a wide range of design options and creative freedom in product development.

Minimal heat impact: Compared to other cutting processes, laser cutting generates only a small amount of heat impact on the material. This minimizes the risk of deformation, discoloration or material fatigue. This is particularly important for sensitive materials or applications where high dimensional accuracy is required.

Automation capability: Laser cutting can be integrated into automated production lines. The process improves productivity through less downtime, optimized process and continuous operation. At the same time, it minimizes scrap through precision control and real-time monitoring. Machine availability increases through error prevention and planned maintenance. Overall, automation leads to more efficient manufacturing and cost savings.

See in our video how effective and fast the ProCutter Thunder laser cutting head is.

Do you want to learn more about our laser cutting heads? Go to our product overview and find the right head for your application.

You may also be interested in this

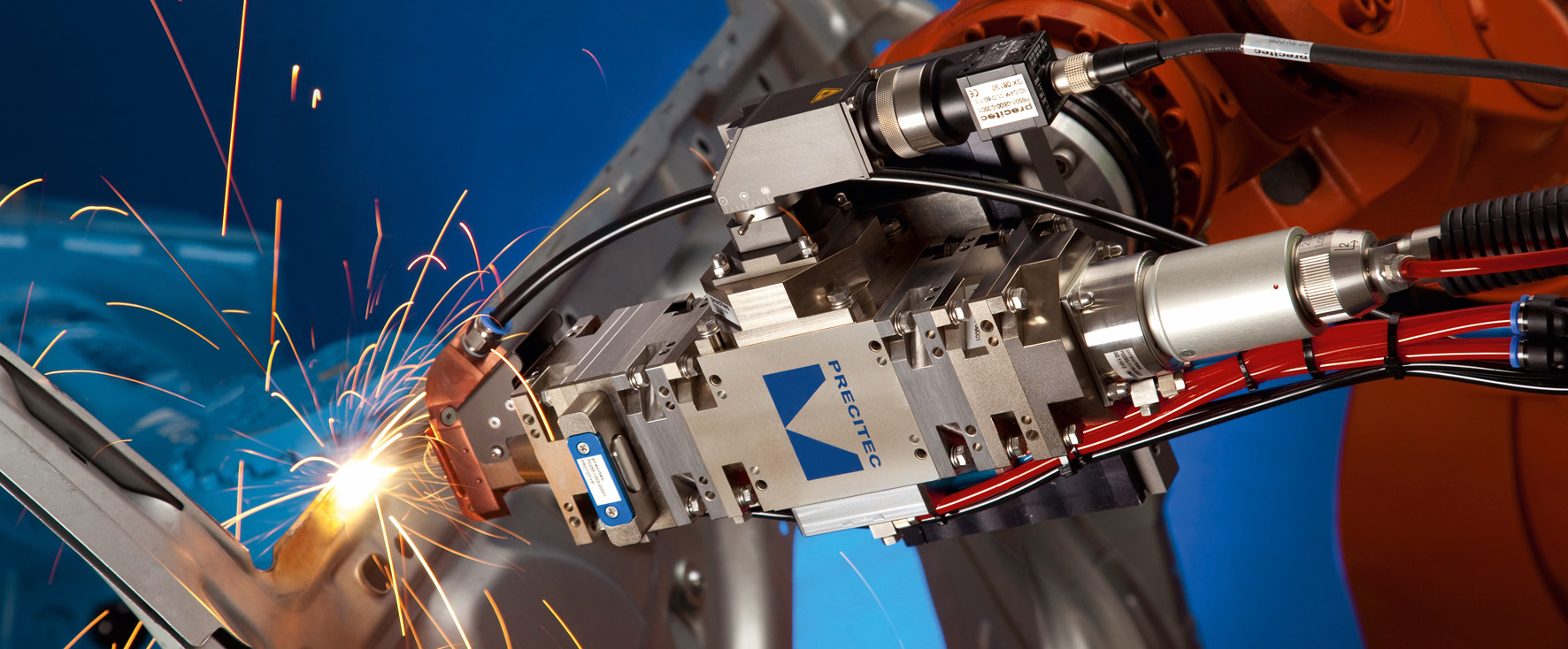

Laser welding as manufacturing process

Laser welding is one of the joining manufacturing processes. A laser beam is used as a heat source to create a.

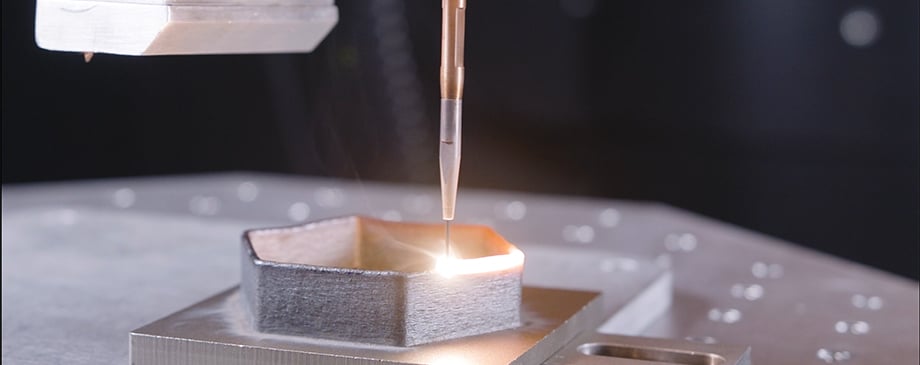

Laser cladding with wire: economical and environmentally friendly

Laser cladding is a promising technology for manufacturing high-quality components, repairing worn parts and coating.

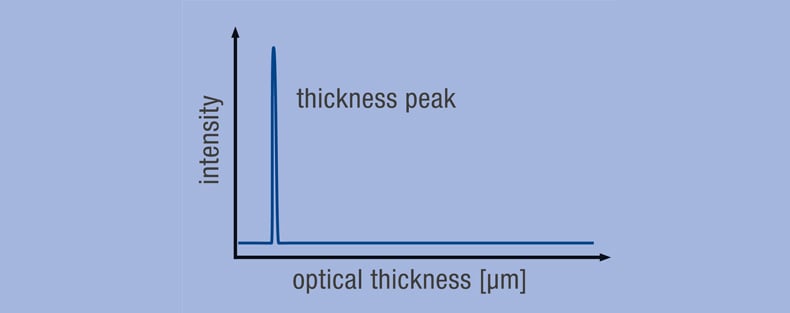

Glass inspection: Two optical metrologies make all the difference

In a challenging economic climate of soaring energy bills and rising raw material prices, glass manufacturers are.